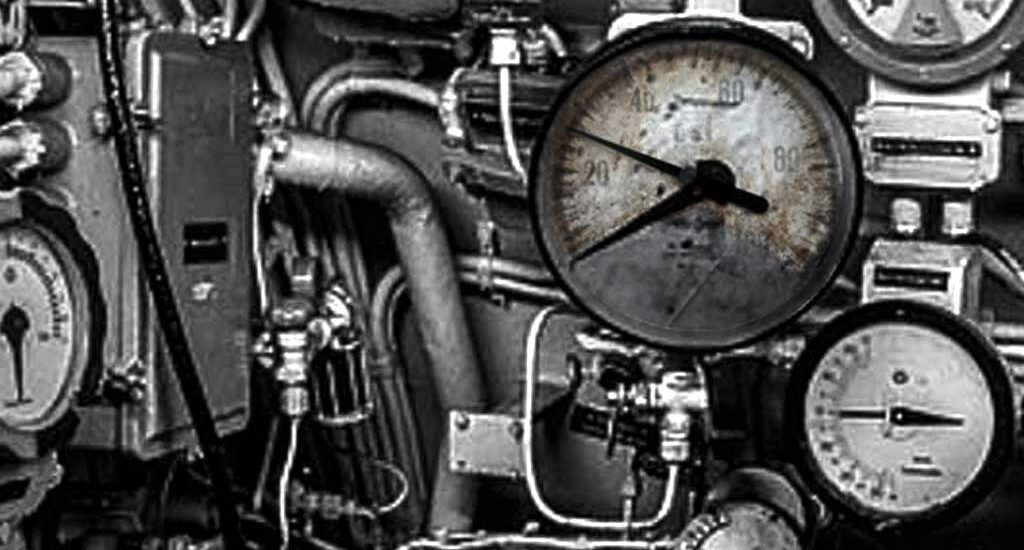

Unlocking the Mysteries of Pressure Gauge Failures: Deep Dive Pressure gauges are the unsung heroes of industrial operations, providing critical data on fluid and gas pressures within systems. However, despite their importance, these instruments are not immune to failure. Understanding the common reasons behind pressure gauge failures is essential for ensuring their longevity, accuracy, and overall efficiency in industrial applications. In this comprehensive guide, we’ll delve into the intricacies of pressure gauge failures, exploring each potential pitfall in detail.

Table of Contents

1. Overpressure: The Silent Culprit

Overpressure remains a silent yet potent threat to pressure gauges. These instruments are meticulously designed with specific pressure ranges in mind. Subjecting a gauge to pressures beyond its intended limit can have dire consequences, ranging from permanent damage to calibration issues, and, ultimately, complete failure. Regular monitoring and adherence to the gauge’s operational limits are the first line of defense against overpressure-induced failures.

1.1 Signs of Overpressure

To identify overpressure issues, operators must be vigilant for signs such as erratic readings, needle oscillations, or, in extreme cases, physical damage to the gauge. These indicators serve as early warnings, prompting timely corrective actions to prevent further complications.

1.2 Preventive Measures

Preventing overpressure-related failures requires a multi-faceted approach. Installing pressure relief valves, employing pressure regulators, and implementing robust maintenance schedules are pivotal strategies. These measures not only protect the gauge but also contribute to the overall safety and efficiency of the entire system.

2. Vibrations and Pulsations: A Mechanical Menace

In industrial environments where machinery-induced vibrations and pulsations are rampant, pressure gauges become susceptible to mechanical stress. The prolonged exposure to such forces can accelerate wear and tear, compromising the accuracy of readings and, ultimately, leading to gauge failure.

2.1 Impact on Accuracy

The impact of vibrations and pulsations on gauge accuracy cannot be overstated. Continuous mechanical stress may cause the gauge’s internal components, including the Bourdon tube, to undergo deformation. This distortion results in inaccurate pressure readings, undermining the reliability of the gauge.

2.2 Mitigating Strategies

Mitigating the effects of vibrations and pulsations involves implementing engineering controls. Isolators or snubbers, strategically placed in the system, absorb excessive mechanical forces, shielding the pressure gauge from potential damage. Additionally, regular inspections and maintenance checks can identify early signs of wear caused by vibrations.

3. Corrosion: The Silent Corrosive Assassin

Corrosion poses a formidable threat to pressure gauges, particularly in industries where corrosive substances are prevalent. Exposure to harsh environmental conditions or corrosive fluids can compromise the accuracy of readings and, over time, weaken the structural integrity of the gauge.

3.1 Corrosion-resistant Materials

Choosing pressure gauges constructed with corrosion-resistant materials is a proactive measure to combat this threat. Stainless steel and other alloys with high corrosion resistance are ideal for environments where exposure to corrosive elements is unavoidable.

3.2 Routine Maintenance

Regular maintenance routines, including thorough cleaning and protective coatings, are crucial in preventing corrosion-related failures. Inspection of the gauge’s external and internal components can identify signs of corrosion early on, enabling timely interventions.

4. Temperature Fluctuations: Navigating the Extremes

Temperature fluctuations, common in many industrial settings, can significantly impact pressure gauge performance. Rapid changes in temperature may cause the gauge’s internal components to expand or contract, leading to accuracy issues and potential failure.

4.1 Impact on Components

Temperature-induced expansion or contraction affects the accuracy of the gauge’s internal components, including the Bourdon tube and the pointer. This phenomenon, known as thermal expansion, results in deviations from true pressure readings.

4.2 Temperature-compensating Features

Selecting pressure gauges equipped with temperature-compensating features is essential in environments characterized by temperature extremes. These features help maintain accuracy by accounting for temperature variations, ensuring reliable readings across a broad temperature range.

4.3 Controlled Environments

Housing pressure gauges in controlled environments, such as climate-controlled enclosures, provide an additional layer of protection against temperature-related failures. This is particularly relevant in industries where temperature fluctuations are inherent to the processes.

5. Clogging and Contamination: A Hidden Saboteur

Undetected particulate matter or foreign substances infiltrating the fluid being measured can lead to the clogging of a pressure gauge’s sensing element or tubing. This not only results in inaccurate readings but can also cause gauge failure.

5.1 Consequences of Clogging

Clogging can impede the movement of the gauge’s internal components, particularly in Bourdon tube-based gauges. This obstruction leads to sluggish response times, erratic readings, and, if left unaddressed, complete failure.

5.2 Filtration Strategies

Implementing robust filtration systems is imperative in preventing clogging-related failures. Properly sized filters, strategically placed in the fluid lines, capture particulate matter and contaminants before they reach the pressure gauge. Regular filter maintenance and replacement schedules are equally crucial.

6. Mechanical Damage: Handle with Care

Physical damage, whether from accidental impacts or mishandling during installation and maintenance, poses a significant risk to pressure gauges. Adherence to proper handling procedures, meticulous installation practices, and routine maintenance checks are imperative in preventing mechanical damage and ensuring gauge longevity.

6.1 Common Causes of Mechanical Damage

Understanding the common causes of mechanical damage is crucial. Accidental impacts, improper handling during transportation, or undue force during installation can lead to dents, bends, or misalignment of critical gauge components.

6.2 Handling Best Practices

Establishing strict handling protocols is essential to safeguard pressure gauges from mechanical damage. This includes employing protective covers during transportation, using proper tools during installation, and conducting thorough inspections post-installation.

7. Poor Installation: Setting the Foundation Right

Incorrect installation practices can lay the groundwork for pressure gauge failure. Overtightening, inadequate sealing, or improper alignment can lead to leaks, misalignment, and damage. Adhering to the manufacturer’s installation instructions meticulously and, when in doubt, seeking professional assistance ensures a trouble-free installation.

7.1 Installation Checklist

A comprehensive installation checklist is a valuable tool in preventing installation-related failures. This checklist should encompass proper alignment, appropriate torque settings, leak checks, and adherence to recommended installation angles.

7.2 Professional Assistance

In cases where the installation process involves complexities or uncertainties, seeking professional assistance is a prudent step. Certified technicians with expertise in pressure instrumentation can ensure that the gauge is installed correctly, minimizing the risk of failures due to installation errors.

8. Age and Wear: The Inevitable Passage of Time

Every mechanical device, including pressure gauges, has a finite lifespan. As components undergo wear and tear over time, accuracy and reliability may be compromised. A proactive strategy involving regular inspection and timely replacement of aging gauges becomes critical in maintaining accurate pressure measurements.

8.1 Signs of Aging

Recognizing the signs of aging in pressure gauges is crucial for proactive maintenance. Symptoms may include faded dial markings, increased response times, or a gradual decline in accuracy. Regular performance assessments help identify aging-related issues early on.

8.2 Replacement Strategies

Establishing a systematic approach to gauge replacement is essential. Manufacturers often provide guidelines regarding the expected lifespan of their products. Following these recommendations and conducting regular performance evaluations aid in determining the appropriate time for gauge replacement.

Conclusion: Fortifying Against Failure ( Pressure Gauge Failure )

Understanding the intricacies of pressure gauge failures is paramount for sustaining the longevity, accuracy, and reliability of these critical instruments. A proactive approach encompassing regular maintenance, proper installation practices, and the selection of gauges suited to specific environments serves as the bedrock for optimal performance.

As industries evolve and technology advances, the landscape of pressure gauge design and functionality continues to improve. Embracing these advancements and staying informed about emerging trends in pressure instrumentation further fortifies systems against potential failures. By staying vigilant and proactive, operators can ensure the seamless operation of pressure gauges, contributing to enhanced safety, efficiency, and overall system performance.

“Ji” Japsin Instrumentation – Since 1974